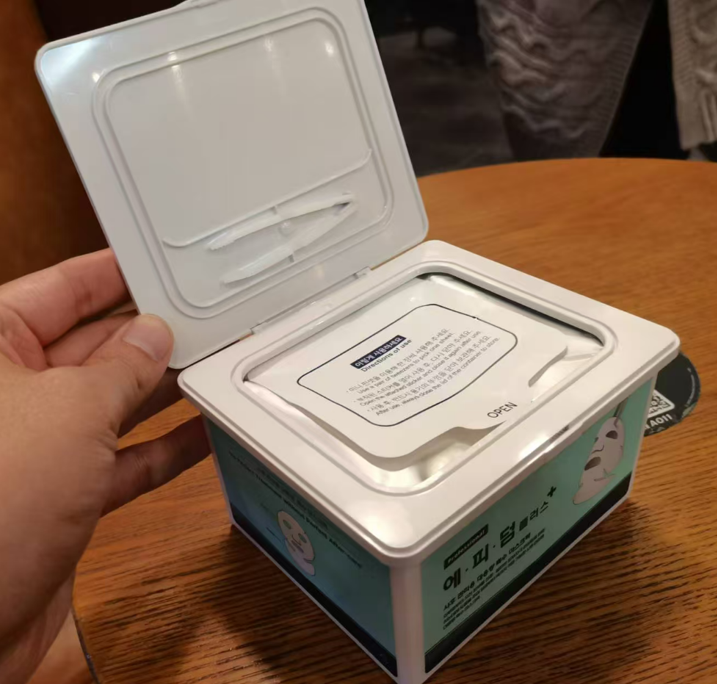

Project Name: Rectangular Facial Mask Box Optimization & Upgrade Project (Including Extended Customization Services for Packaging Materials)

This case focuses on the collaborative optimization of cosmetic facial mask boxes and supporting bottle packaging materials. By adjusting the structure of the original rectangular mask box, we balance transportation cost control and stacking practicality, helping customers enhance their products’ overall competitiveness. As a powerful China bottle supplier, professional packaging material manufacturer, and China bottle manufacturer, we rely on a mature localized supply chain system, independent mold workshop, and senior design team. With customer needs at the core, we provide one-stop customization services from design optimization, prototype sampling, mold making, mass production to supporting labeling—these are the core competitive advantages that define us as a leading China bottle supplier.

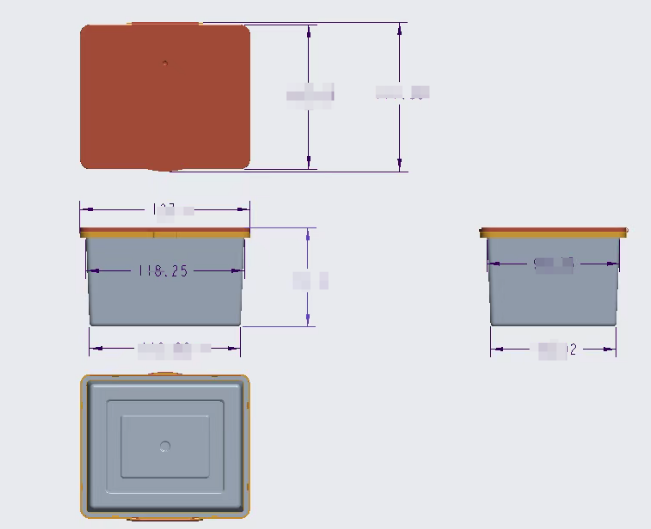

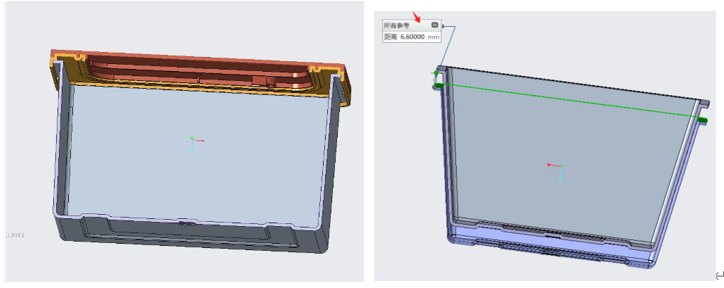

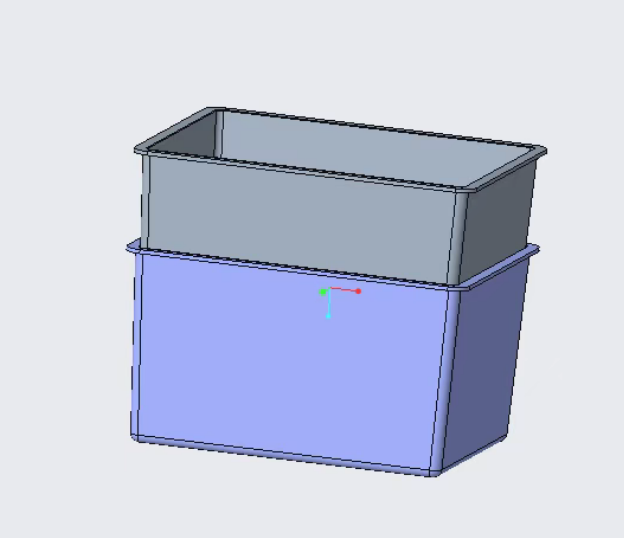

The original product was a standard rectangular facial mask box. After cost accounting and analysis, we proposed an optimization plan: keeping the upper size of the box unchanged and shrinking the bottom inward by a certain margin. The core goal is to reduce the transportation cost of packaging materials and improve the efficiency of warehousing and stacking. This optimized design does not affect the integrity of the product appearance and usability; on the contrary, it enhances the convenience of transportation and storage through structural adjustment.

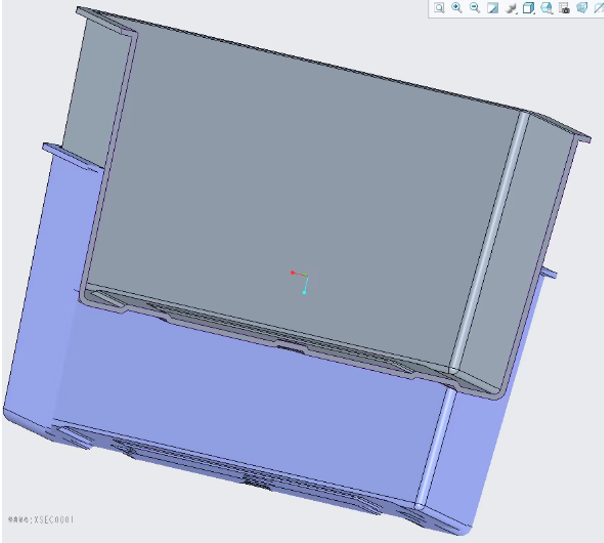

The optimized mask box enables stable stacking (see attached stacking diagram), effectively saving warehousing space and transportation load, and significantly reducing packaging material loss and logistics costs in cross-border transportation—this cost control capability is one of the core advantages we have developed as a China bottle supplier with years of experience in foreign trade scenarios. To verify the feasibility of the plan, we responded quickly relying on our own mold workshop.

First, we printed a 3D prototype for physical testing according to the optimized drawings. After confirming the structure was reasonable and met expectations, we immediately launched the mold making process, which was 30% shorter than the industry average cycle. Finally, we successfully mass-produced qualified products, efficiently meeting the customer’s cross-border delivery needs.

After the final products are delivered, we also provide customized labeling services for customers, supporting both side labeling and flat surface (box cover top) labeling solutions to meet the packaging display needs of different brands

As a professional customized packaging enterprise rooted in Guangzhou and serving the global market, we not only focus on the optimization and customization of cosmetics packaging such as facial mask boxes, but also take the core identity of a China bottle supplier to specialize in the R&D and production of various daily chemical and skincare bottle packaging materials. Our core products include shampoo bottles, body wash bottles, lotion bottles, essence bottles, emulsion bottles, face cream jars and other full-series skincare and daily chemical packaging materials. With cost-effective advantages brought by localized production, flexible small-batch customization capabilities, comprehensive cross-border supply chain services (including labeling 。Silk printed ,hot stamping and sandblasht , and compliance testing support), and a stable quality control system, we have become a trusted China bottle supplier and packaging material manufacturer for customers in dozens of countries around the world. We can tailor highly adaptable packaging customization solutions according to customers’ brand positioning and target market needs, helping them seize overseas markets.